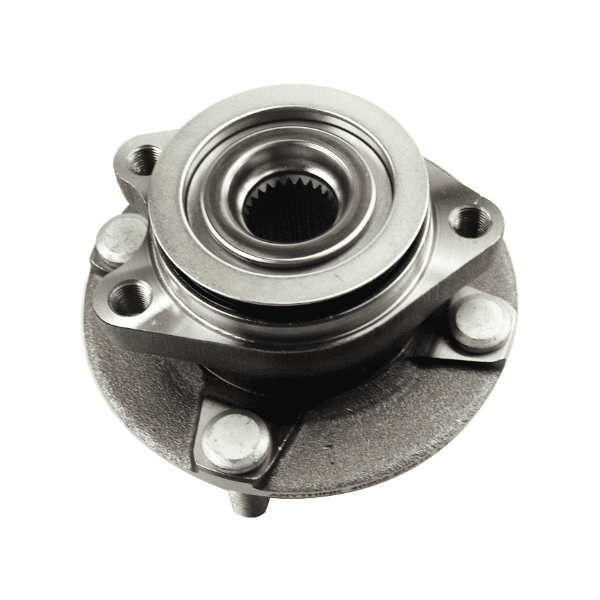

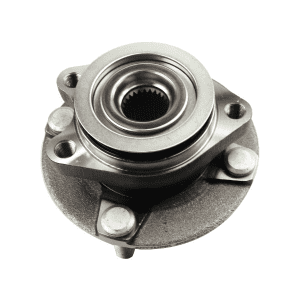

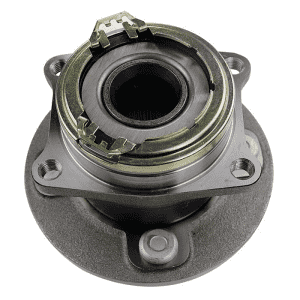

Self-aligning ball bearing 2218

*Specifications

|

2218 Bearing Detail |

|

| Brand | Self-aligning ball bearing bearings |

| Item | Self-aligning ball bearing 2218K bearings |

| Material | GCr15 steel,carbon steel,stainless steel etc. |

| Precision | P0,P2,P5,P6,P4 |

| Clearance | C0,C2,C3,C4,C5 |

| Bearing size | 0-200 mm outer diameter 0-400mm |

| Cage type | brass;steel plate,nylon,aluminium alloy etc. |

| Ball Bearings Feature | Long-life with high quality |

| Low-noise with strict controlling the quality of Ruben bearing | |

| High-load by the advanced high-technical design | |

| Competitive price, which has the most valuable | |

| OEM service offered, to meet the customers requirements | |

| Application | gearbox,auto,reduction box,engine machinery,mining machinery,bicycles,etc |

| Bearing Package | Pallet,wooden case,commercial packaging or as customers requirement |

| Lead Time : | ||||

| Quantity(Pieces) | 1 – 300 | >300 | ||

| Est. Time(days) | 7 | To be negotiated | ||

Packaging & Delivery:

Packaging Details: Industrial; Single box + Carton + Wooden Pallet

1.Self-aligning Ball Bearing Introduction :

Self-aligning ball bearings. Self-aligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted raceway grooves in the inner ring. They are available open or sealed.

2.Self-aligning Ball Bearing Description :

Self-Aligning Double Row Ball Bearings are designed to work in applications where severe misalignment exists whether from mounting or shaft deflection. The concave raceway of the outer ring in combination with two rows of balls operate over a wide range of contact angles. Furthermore it aligns itself correctly with the shaft and assembly without causing undue stress on the rest of the bearing assembly.

3.Self-aligning Ball Bearing Series :

Self-Aligning Double Row Ball Bearings come in three numeric series which represent the maximum specified degree of misalignment and loads:

1200 Series – Can be misaligned 2.5°

1300 Series – Can be misaligned 3.0°

2200 Series – Can be misaligned 2.5° but has higher load ratings is and wider than the 1200 Series

*Advantage

SOLUTION

– At the beginning, we will have a communication with our customers on their demand, then our engineers will work out an optimum solution based on the customers’ demand and condition.

QUALITY CONTROL (Q/C)

- In accordance with ISO standards, we have professional Q/C staff, precision testing instruments and internal inspection system, the quality control is implemented in every process from material receiving to products packaging to ensure our bearings quality.

PACKAGE

– Standardized export packing and environment-protected packing material are used for our bearings, the custom boxes, labels, barcodes etc. can also be provided according to our customer’s request.

LOGISTIC

– Normally, our bearings will be sent to the customers by ocean transportation due to its heavy weight, airfreight, express is also available if our customers need.

WARRANTY

– We warrant our bearings to be free from defects in material and workmanship for a 12 months period from the shipping date, this warranty is voided by non-recommended use, improper installation or physical damage.

We have completely production line, and are always strictly controlling each process of production, from raw material making, turning to heat treatment, from grinding to assembly, from cleaning, oiling to packing etc. The operation of each process is very meticulously. In the process of production, through self-inspection, follow inspection, sampling inspection, full inspection, such as strict as quality inspection, it made all the performances reached the international standard. At the same time, the company set up advanced testing center, introduced the most advanced testing instrument: three coordinates, length measuring instrument, spectrometer, profiler, roundness meter, vibration meter, hardness meter, metallographic analyzer, bearing fatigue life testing machine and other measuring instruments etc. About the quality of the product to entire prosecution, the comprehensive performance of comprehensive inspection products, ensure JITO to reach the level of zero defect products!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WhatAapp

Judy

-

WeChat

Judy

-

Top